Houston’s leading HVOF thermal spraying experts

11718 North Garden, Building G.

Houston, Texas 77071

(832) 603-9663

Welcome to Houston Metal Spraying! Our parent company Houston Pump and Gear is known around the globe for providing full-service gearbox and pump repairs. Here, at Houston Metal Spraying, we are the premier HVOF thermal spray system experts, serving clients across Texas and North America.

If you are looking for high-quality and affordable thermal spraying services, call Houston Metal Spraying first. We have competitive pricing and only use the highest quality materials and state-of-the-art technology.

1

2

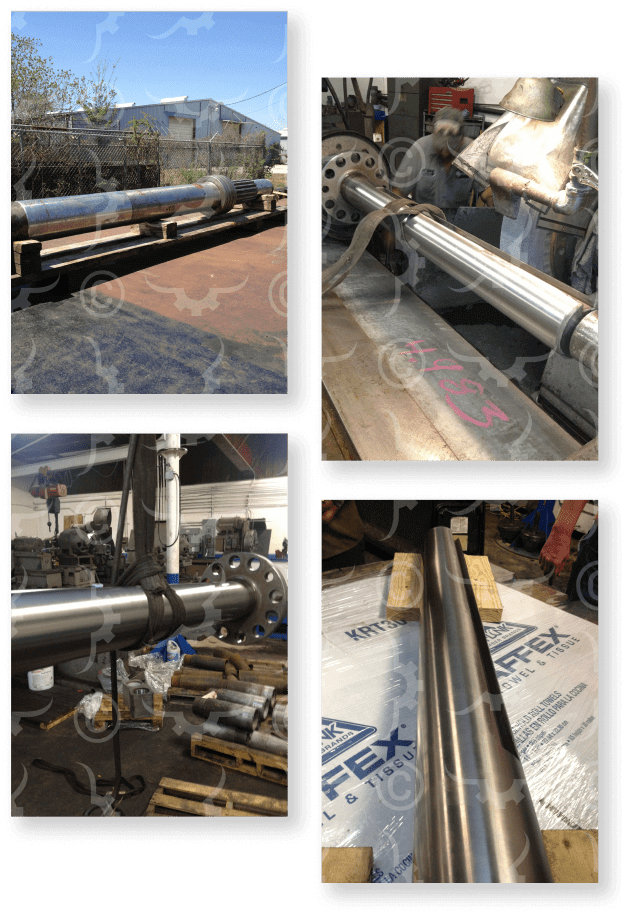

Our thermal spray coating clients hail from industries ranging from Food Manufacturing to Power Generation to Automotive Manufacturing, and beyond. Essentially, if you are in any industry that has a conveyor, a shaft is involved. After extensive use, any shaft will require reliable HVOF spray coating services. If you are experiencing any of the following issues with your equipment, we have a solution:

Coordinate the delivery of your materials to our facilities

Inspect the shaft and begin the HVOF spray process

Apply the HVOF thermal spray coating and build it up to size

Recondition the shaft back to OEM spec

While each case is different, you can rest assured knowing that HVOF thermal spraying is cost effective and is more affordable than purchasing or manufacturing a new piece.

To discuss exact costs, give us a call. One of our technicians can review your specific requirements to provide a free project quote.

We work with a number of different materials for many different applications. We can build up Nickel, Stainless Steel, Carbide, Inconel, Hastelloy, Carpenter 20, Stellite, and many other alloys. Not sure what best fits your application? We can recommend the best solution for your equipment. Just give us a call to discuss your needs.

While each project is different, depending on the materials used and equipment size, we pride ourselves on offering the quickest turnaround time in the industry. You can expect to receive your reconditioned unit within weeks, compared to months as with our competitors or OEM manufacturers. If you’re in need of immediate assistance, we also offer 24/7 emergency service and can turn parts around in as little as 48 hours.

Just like our turnaround time, our warranty can’t be beaten. We provide a warranty for 12 months from the date of installation. This means that if you don’t install your equipment immediately, the warranty won’t start until it is in use.

Houston’s leading HVOF thermal spraying experts